The working principle of the concrete tanker truck is to take out the power from the truck chassis through the pick-up device, drive the pump of the hydraulic system, convert the mechanical energy into hydraulic energy, and then transfer it to the motor, which in turn drives the reducer. Eventually the reducer drives the mixing tank to mix the concrete. In this process, the oil pump, motor and reducer are the key components, which work together to ensure that the concrete is kept in a homogeneous mixing state during transport. So what are the roles of these three main components?

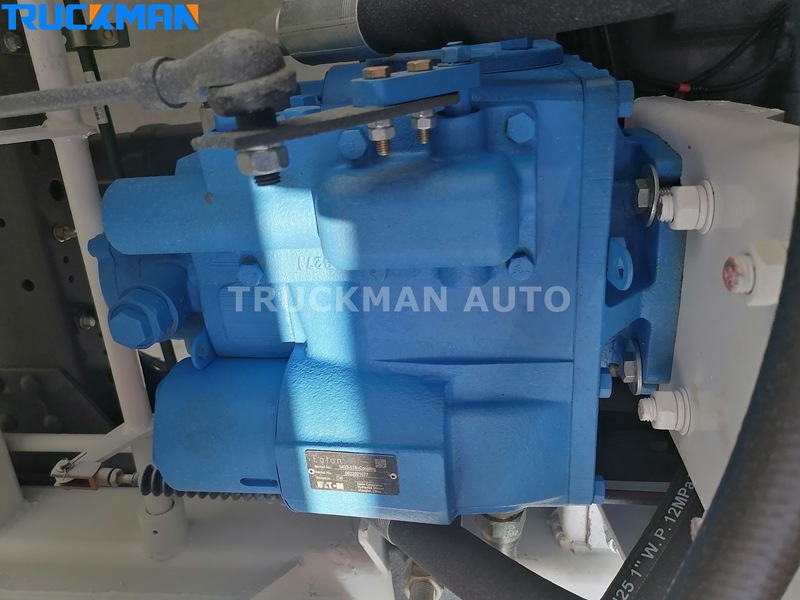

1. Hydraulic Pump

Hydraulic pump selection of the USA EATON brand, Italy's BONFIGLIOLI and other brands, its role is to provide a constant flow of power for the hydraulic oil.

2. Hydraulic Motor

The hydraulic motor also adopt the famous brand, such as EATON, PMP etc. The role of the motor is to convert the power of the hydraulic fluid into mechanical power, which is transmitted to the reducer.

3. Reducer

Reducer are ZF from Germany and PMP brand from Italy, which are used to reduce the speed of the hydraulic motor to meet the working requirements of the mixing device.